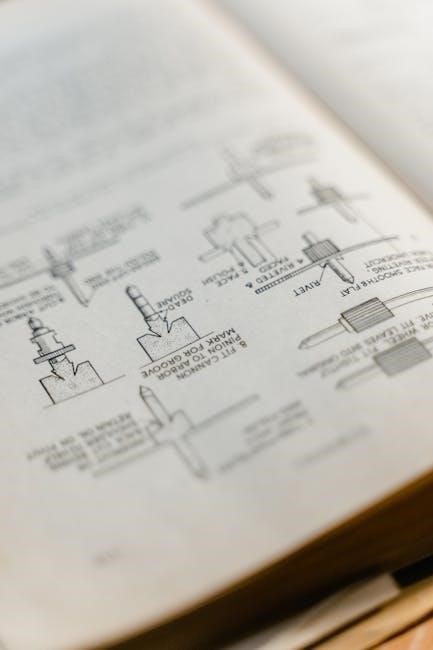

manual transaxle diagram

A manual transaxle diagram provides a detailed visual representation of the components and their interactions within a manual transmission system, essential for understanding its operation and maintenance.

1.1 Purpose and Importance of a Manual Transaxle Diagram

A manual transaxle diagram is a vital tool for understanding and working with manual transmission systems. Its primary purpose is to provide a clear, visual representation of the components, such as gears, shafts, and synchronizers, and how they interact. This diagram is essential for technicians, mechanics, and enthusiasts to diagnose issues, perform repairs, and maintain the system effectively. By studying the diagram, one can identify potential problems, such as worn clutches or misaligned gears, and understand how torque flows through the system. It also serves as an educational resource for learners, helping them grasp the mechanical principles behind power transmission. Regular reference to the diagram ensures proper maintenance, preventing premature wear and optimizing the system’s efficiency and performance.

1.2 Overview of the Manual Transaxle System

The manual transaxle system is a complex mechanism designed to transmit power from the engine to the wheels while allowing for manual gear changes. It consists of key components such as gears, shafts, and synchronizers, which work together to adjust speed and torque. The system includes an input shaft, output shaft, and counter shaft, each playing a critical role in power transmission. The clutch is integral to this system, enabling the driver to engage and disengage the engine from the transmission during gear shifts. Understanding the layout and operation of these components is essential for proper maintenance and repair. The manual transaxle diagram provides a visual breakdown of these parts, making it easier to comprehend their interactions and ensure smooth functionality.

Key Components of a Manual Transaxle

A manual transaxle comprises essential parts like gears, shafts, the clutch, synchronizers, and bearings, each playing a vital role in transmitting power and enabling smooth gear transitions.

2.1 Gears and Shafts: Input, Output, and Counter Shafts

Gears and shafts are critical components of a manual transaxle, enabling power transmission and gear changes. The input shaft connects to the clutch, transferring power from the engine. The output shaft delivers power to the wheels, while the counter shaft houses gears that adjust speed and torque. Spur gears and helical gears are commonly used, with synchronizers ensuring smooth gear engagement. Bearings support these shafts, reducing friction and wear. Proper alignment and lubrication are essential for optimal performance and longevity of the transaxle system.

2.2 Clutch and Its Role in the Transaxle System

The clutch is a vital component in the manual transaxle system, acting as an intermediary between the engine and the transmission. Its primary function is to engage and disengage the engine from the transaxle, allowing smooth gear shifts. When the driver presses the clutch pedal, the clutch disengages, temporarily separating the engine from the transmission. This action prevents grinding of gears during shifting. The clutch consists of a pressure plate, clutch disc, and release bearing. Proper clutch operation ensures efficient power transmission and prevents wear on other components. Over time, the clutch can wear out, leading to issues like slippage or difficulty shifting gears, requiring eventual replacement to maintain optimal performance.

Torque Flow in a Manual Transaxle

Torque flows from the engine through the clutch and gears, engaging specific shafts to transmit power to the wheels, ensuring efficient and controlled energy distribution.

3.1 Understanding the Path of Power Transmission

The path of power transmission in a manual transaxle begins with the engine, where torque is generated and transferred through the clutch to the input shaft. The clutch engages and disengages, allowing the driver to shift gears smoothly. Once the clutch is engaged, the input shaft spins, turning the gears on the counter shaft. These gears rotate in the opposite direction due to the gear mesh, ensuring the output shaft spins in the same direction as the input. The synchronizer ensures seamless gear engagement, allowing the driver to shift gears without grinding. Finally, the output shaft transmits the torque to the differential, which distributes power to the wheels, enabling the vehicle to move forward or reverse efficiently;

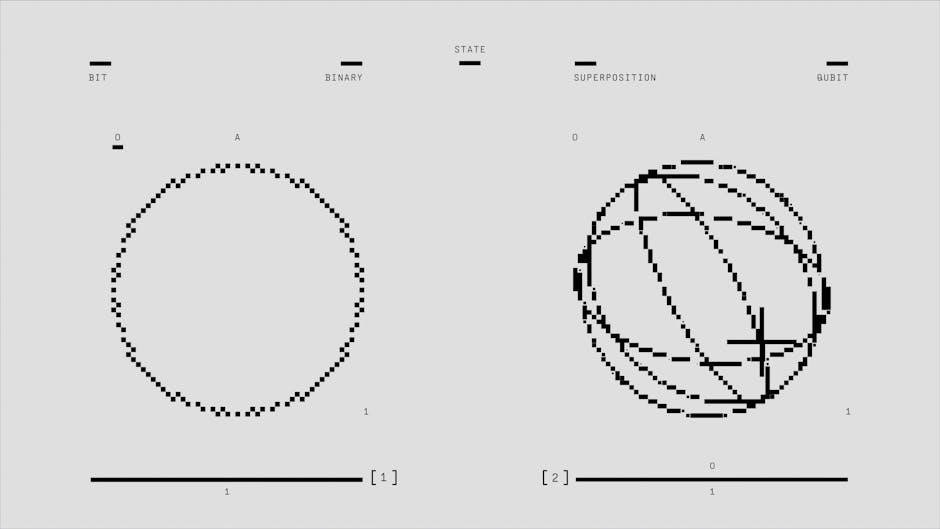

3.2 Synchronizer Operation and Gear Engagement

The synchronizer mechanism ensures smooth gear engagement by synchronizing the speed of the gear and the shaft. When the driver presses the clutch, the input shaft stops rotating, allowing the synchronizer to align the gear with the output shaft. The synchronizer hub and sleeve assembly engage the desired gear, matching their rotational speeds. This prevents grinding and ensures a seamless transition between gears. The synchronizer’s frictional force helps lock the gear in place, maintaining engagement. Proper synchronizer operation is critical for smooth shifting, driver comfort, and system longevity. Understanding this process is essential for diagnosing issues like hard shifting or gear disengagement problems. Regular lubrication and maintenance are vital to keep the synchronizer functioning efficiently.

Maintenance and Troubleshooting

Regular lubrication of gears and shafts is essential for smooth operation. Inspect for worn components, such as the clutch, and address issues promptly to prevent further damage.

4.1 Common Issues and Diagnostic Techniques

Common issues in manual transaxles include worn clutches, synchronizer problems, and gear misalignment. These often manifest as difficulty shifting gears or a grinding noise during operation; Diagnostic techniques involve inspecting for wear on components like gears and bearings. Listening for unusual noises, such as clunking or whining, can help pinpoint issues. Visual inspections of the clutch and gear engagement are also critical. Additionally, testing the transmission under various driving conditions can reveal problems like slippage or hesitation. Early detection of these issues is crucial to prevent costly repairs and ensure smooth operation. Regular maintenance and prompt addressing of symptoms are key to extending the lifespan of the transaxle system.

4.2 Lubrication and Gear Maintenance Practices

Proper lubrication is essential for the longevity and smooth operation of a manual transaxle. The system relies on transmission fluid to reduce friction between moving parts and prevent overheating. Regular fluid changes, typically every 30,000 to 60,000 miles, are recommended to maintain viscosity and cleanliness. Gear maintenance involves inspecting and cleaning components like gears, bearings, and synchronizers. Worn or damaged parts should be replaced promptly to avoid further damage. Additionally, applying the correct type of grease to gear shafts and bearings ensures proper lubrication. Neglecting these practices can lead to premature wear, corrosion, and eventual system failure. Regular maintenance not only enhances performance but also extends the lifespan of the transaxle.

Manual Transaxle Construction and Design

The manual transaxle is designed for efficient power transmission, featuring a compact, lightweight structure that enhances fuel efficiency and vehicle performance.

5.1 Engineering Principles Behind the System

The manual transaxle is built on foundational engineering principles that prioritize efficiency, durability, and precision. Gear ratios are carefully calculated to optimize power delivery across various driving conditions, ensuring smooth acceleration and control. The system incorporates bearing-supported shafts to minimize friction and extend component lifespan. Lubrication plays a critical role, with oil baths or pressure-fed systems ensuring consistent cooling and wear reduction. Synchronization mechanisms are designed to enable seamless gear transitions, reducing wear on engaging teeth. These principles work together to create a reliable, high-performance transmission system capable of withstanding the demands of both urban and high-speed driving environments.

- Material selection focuses on strength-to-weight ratios for optimal performance.

- Friction reduction techniques enhance energy efficiency and reduce heat buildup.

5.2 Evolution of Manual Transaxle Technology

The manual transaxle has evolved significantly over the years, driven by advancements in engineering and the need for improved performance. Early systems relied on non-synchronous designs, which were prone to wear and difficult to operate. The introduction of fully synchronized gearboxes in the mid-20th century revolutionized manual transmissions, enabling smoother shifting and reducing driver fatigue. Modern systems incorporate lightweight materials, such as aluminum and carbon fiber, to enhance efficiency and reduce weight. Electronic integration, like clutch-by-wire systems, has further refined operation, offering precise control and improved fuel efficiency. Continuous innovation ensures manual transaxles remain relevant, blending tradition with cutting-edge technology to meet contemporary automotive demands.

- Improved synchronizer designs have reduced shifting effort and noise.

- Advanced lubrication systems now offer better thermal management.